Last updated on February 28th, 2024 at 10:07 am

Before an engineer arrives to install a new boiler you will need to clear the installation area, understand your existing system and check you are compliant with Gas Safety regulations.

Warmable is here to guide you through the essential steps to ensure your home’s ready for a smooth transition. Preparing for a new boiler installation can be as crucial as the installation itself. From understanding your current heating system to considering the practicalities, we’re here to help you tick off every box on your checklist.

We know the importance of a hassle-free boiler installation. That’s why we’ve crafted a comprehensive checklist to prepare your home effectively. Warmable can even schedule an on-site visit from a boiler specialist, wherever you are living in the UK. Let’s dive into what you will need to do before the engineers arrive.

Clearing the Installation Are

Before the boiler installation team arrives, it’s essential to prepare the space where the boiler will be installed. This not only facilitates a quicker installation process but also helps ensure the safety of all involved. First and foremost, it’s your responsibility to ensure the immediate area is free from any clutter or personal belongings.

You’ll need to remove items such as:

- Furniture

- Rugs

- Decorative items

Ensure there’s enough room for the engineers to work comfortably around the boiler. A clear pathway should be maintained, allowing them to bring in tools and equipment with ease. Remove any obstacles that could hinder access to the installation site.

It’s also important to consider the working conditions. Good lighting and ventilation are crucial for a safe working environment. If the boiler is being installed in a basement or a space with limited natural light, we might need to set up additional luminance to aid the engineers.

In addition to clearing the area, you should also cover any surfaces or belongings in proximity to the installation site. Dust sheets or protective coverings can safeguard against dust and debris that are often byproducts of the installation process. These proactive measures go a long way in preventing any unnecessary clean-up afterwards and protect your possessions from potential damage.

Understanding Your Existing System

Before the new boiler arrives, it’s crucial to get acquainted with the current heating setup. Identifying the type of system that’s already in place helps in anticipating the extent of the work involved. Typically, systems fall into one of three categories: combi, conventional, or system boilers.

We recommend documenting the existing setup, which includes noting down the location of the current boiler, the pipework, and radiators, as well as the type and location of the thermostat. By doing so, this information can highlight potential areas that may need adjustments or upgrades to accommodate the new system.

Another important aspect is considering the age and condition of your current system. Older boilers and their associated components may require more time to remove and may dictate additional considerations for compatibility with the latest technology.

Lastly, you’ll want to assess the efficiency and performance of the current system. This can be crucial in understanding how much improvement the new boiler will bring in terms of energy savings and heating power. Here are few key points to check:

- The energy efficiency rating of the existing boiler

- The condition of the current radiators and pipes

- Any known issues with heating consistency or water pressure

Armed with this knowledge, you will be better prepared to support the installation team and ensure a smoother transition to the new boiler.

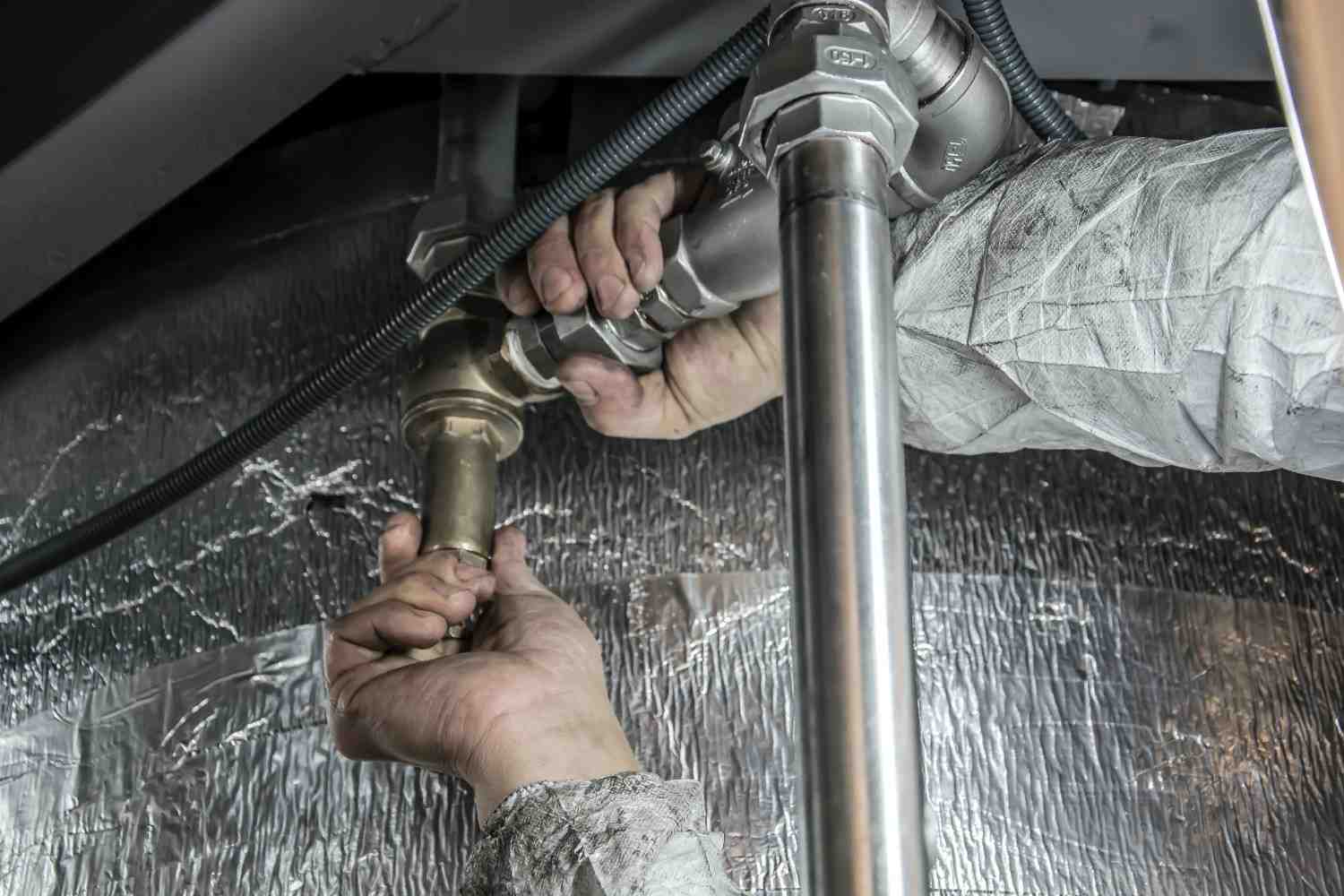

Assessing the Plumbing and Heating Infrastructure

It’s crucial to assess your existing plumbing and heating infrastructure before having a new boiler installed. Getting a clear understanding of the layout and condition of our current system not only helps you understand what can be kept or needs replacing but also helps the boiler installation team to provide an accurate quote and prepare for any potential challenges.

Age and Material of Pipework: The age and material of your existing pipes play a significant role in determining whether they can handle the new boiler. Older pipes might need replacing to ensure they can cope with the efficiency and pressure of a modern system.

Water Pressure Checks: A fitter will perform water pressure tests to ensure that the pressure is within the acceptable range for a new boiler. Low pressure can affect a boiler’s efficiency and reliability, so we may need to address this prior to installation.

Heating System Evaluation: We’ll take a closer look at your current heating system, which includes:

- Radiator efficiency and locations

- Underfloor heating presence and condition

- Hot water cylinder and storage system

Evaluating each component, we’ll decide if additional works are necessary to optimise our heating distribution alongside the new boiler.

Assessing our plumbing and heating infrastructure is more than just a check-up; it’s a roadmap for seamlessly integrating the new boiler with our home’s existing features and ensuring optimal performance.

Checking for Gas Safety Compliance

Before you schedule a boiler installation, it’s crucial to ensure that your home is compliant with gas safety regulations. Gas safety is not just a legal requirement but also a vital aspect of maintaining the wellbeing of anyone who enters your home.

Firstly, check if your property has a Gas Safety Certificate. This document proves that your gas appliances, pipes, and flues are safe and meet the legal standards. If your certificate is outdated, it’s imperative to arrange for a registered Gas Safe engineer to inspect your gas system and provide a new certificate.

Assessing the venting path is part of the compliance checklist. Your boiler needs adequate ventilation to operate safely, preventing the potential buildup of harmful gases. Make sure that your boiler’s location has proper clearance and that no vents are obstructed.

Lastly, install a carbon monoxide detector near the boiler. Carbon monoxide is a silent killer, being odourless and colourless. By detecting it early, we can help prevent any accidents related to gas leaks.

The installation team will thoroughly inspect and test all gas connections and supply lines to ensure they’re not only compliant but that they’re in optimal condition for the new boiler. The priority is to keep your home safe while also providing the professional installation you expect.

Ensuring Adequate Ventilation

When preparing for a boiler installation, proper ventilation is critical. Boilers need a constant flow of air to function safely and efficiently. Without adequate ventilation, there’s a risk of carbon monoxide buildup, which can be extremely hazardous to our health.

To ensure that your boiler will operate safely, the installation space will be checked for any existing vents. It’s essential to verify that these are unobstructed and clean, as any blockages could impede airflow. Here’s what the engineer will look at:

- Location of air inlets and outlets

- Proximity to windows and other openings

- Airflow requirements for the specific boiler model

In some cases, additional ventilation may need to be created to meet the manufacturer’s recommendations. This could mean installing new vents or making adjustments to the existing ones.

Particular attention will be paid to the boiler room’s door, as it should be ventilated correctly or fitted with a louver to facilitate the entry of fresh air. The size and type of boiler installation often dictate the amount of ventilation required. For instance, open flue boilers require more outside air to support combustion than room-sealed boilers, which typically draw air directly from the outside.

It’s also important to consider future maintenance access to ensure ventilation systems remain functional over time. Blocked air passages are more than just a compliance issue – they can directly impact the longevity and performance of the boiler. Regular checks post-installation are an integral part of safely maintaining a well-ventilated system which can be assessed during an annual boiler service.

Conclusion

We’ve covered the essential steps to prepare your home for a boiler installation, focusing on safety and efficiency. Ensuring gas safety compliance and proper ventilation is crucial for a successful setup. By following our checklist, you’ll create a safe environment for your new boiler and maintain it in top condition. Remember, a well-prepared home leads to a smoother installation process and a more reliable heating system.

Frequently Asked Questions About Boiler Installation

What Is A Gas Safety Certificate, And Why Is It Important?

A Gas Safety Certificate is a document that confirms your gas appliances have been checked and are safe to use. It is crucial to have this certificate before installing a boiler to ensure compliance with safety regulations and to prevent any potential gas leaks or hazards.

How Does Proper Venting Affect Boiler Installation?

Proper venting ensures that harmful gases are safely expelled from the premises and fresh air is available for combustion. This is essential to prevent the buildup of carbon monoxide, which can pose serious health risks.

Why Should A Carbon Monoxide Detector Be Installed Near A Boiler?

A carbon monoxide detector is vital near a boiler as it will alert residents if there is carbon monoxide present, which is a potentially lethal, odourless and colourless gas. Early detection can save lives by allowing for quick action.

What Should Be Inspected And Tested Concerning Gas Connections And Supply Lines?

All gas connections and supply lines must be inspected and tested for leaks, proper pressure, and wear and tear. Ensuring they are in optimal condition is essential for safety and the efficient operation of the new boiler.

What Factors Should Be Considered For Adequate Boiler Ventilation?

When checking for proper ventilation, consider the location of air inlets and outlets, proximity to windows and other openings, and the specific airflow requirements for the boiler model. Adequate ventilation is necessary to avert dangerous carbon monoxide accumulation.

Is It Possible To Create Additional Ventilation For A Boiler Installation?

If the existing ventilation is insufficient, it may be necessary to create additional ventilation to meet the boiler’s requirements and maintain safety standards. This should be done according to professional guidelines and building codes.

How Often Should The Ventilation System Be Checked Post-Boiler Installation?

The ventilation system should be regularly checked post-installation to ensure that it continues to provide adequate airflow and prevent carbon monoxide buildup. Frequency of checks depends on manufacturer recommendations and local regulations.